Wow, Rich, something does seem odd here. If you've done 20 guitars, you have more experience than me and Hesh put together.

Thanks for the complements Hesh. I always lay out my builds in Autocad (I have a very funny story to tell about this some othertime). To me, it helps eliminate the posiblilty of problems. But this works for me, and maybe not for everyone else.

Here's a little reminder tutorial for those that may find it usefull.

So, I will draw out the front and tail edge of the body, than draw a straight line between them.

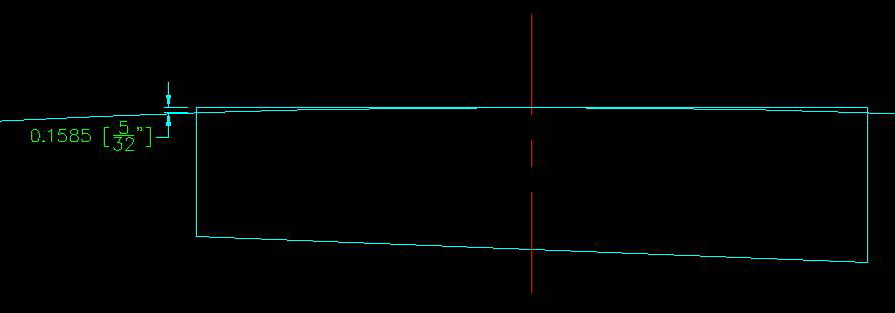

Next I draw in the 25' radius (I don't use this buy there are many that do so I will encorporate it)

Notice that it is at the very center of the body and that the gap between the "flat" line of the top and the curve is 5/32" which is greater than Rich's 1/8"+/- gap.

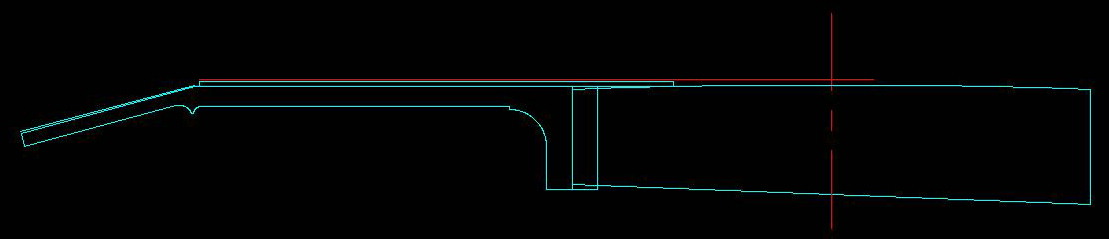

So now we take the neck layout. The red line represents our 25.4 scale at the top of the frets.

And we lay it out on the body which is sanded to 25' radius.

And of course we have our gap just like Rich's

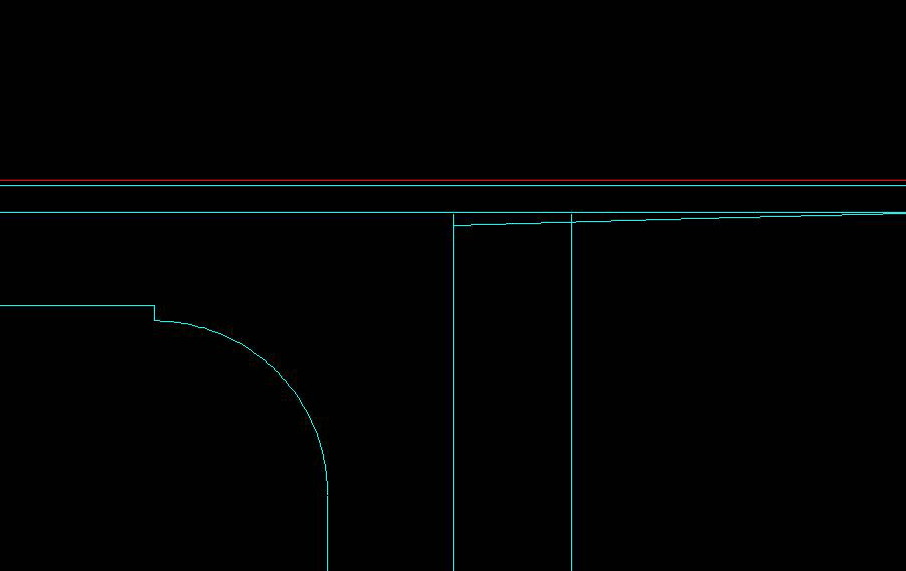

Now we set the neck by shaving the heel.

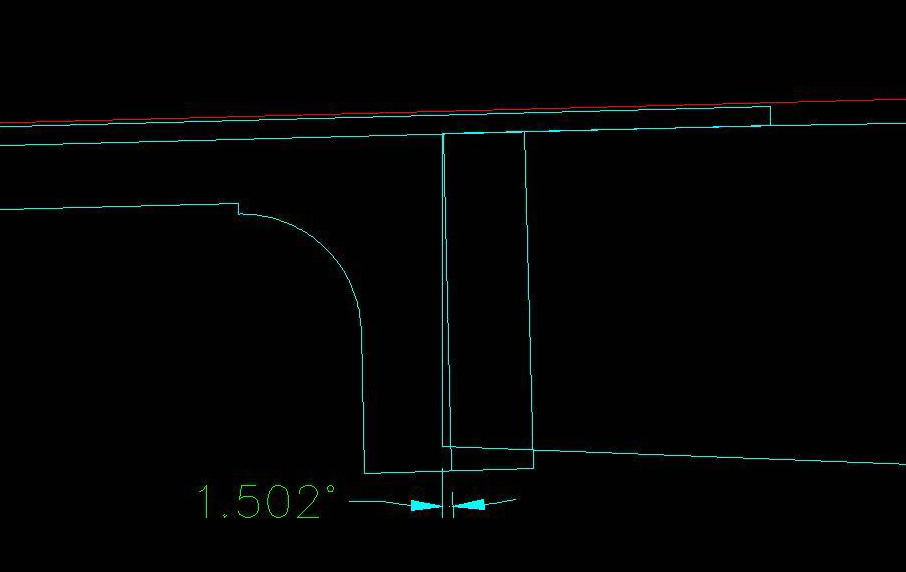

And here is the angle we need to trim off the heal (Look familiar anyone)

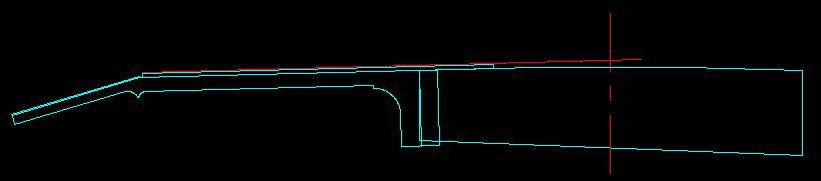

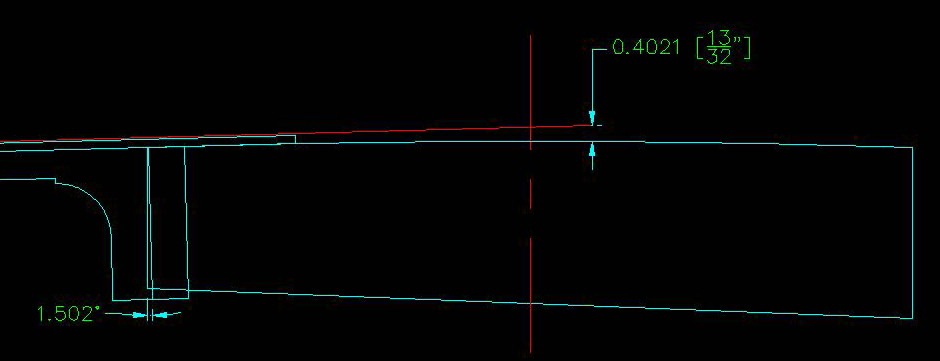

Now here is the height at the bridge that we are looking for, maybe even a bit low (by about 1/32")

So this shows why 25' radius has been used to set the neck for a 3/8" bridge height.

Hope this helps someone, it helped me remember just by doing this.

Cheers All.

_________________

My Facebook Guitar Page"There's really no wrong way, as long as the results are what's desired." Charles Fox

"We have to constantly remind ourselves what we're doing....No Luthier is putting a man on the moon!" Harry Fleishman

"Generosity is always different in the eye of the person who didn't receive anything, but who wanted some." Waddy Thomson